Brand message

Mission

Delivering products that are lights of hope and opening the way to an abundant future for all people.

Vision

By being proactive, not passive, we will continue to be a fresh light that clients approach first.

Value

- ◆ We respond with both speed and flexibility.

- ◆ We value the spirit of challenge.

- ◆ We deliver solutions that are a step ahead through creative interpretations.

- ◆ Internal voices reflect society’s perspective; therefore, we emphasize a willingness to listen to opinions.

Responsiveness

01

Achievements and responsiveness

Keeping dialogues with you in our mind for a long time, SHINKOH ELECTRONICS CO.,LTD.. constantly has been taking on new challenges. The challenge creates new technologies and the new technology makes next challenges possible –. We will proceed with that fulfilling product developments and we also will walk as your reliable partner.

02

Flexible responsiveness tailored to needs

We generously demonstrate our technical ability and design perfect products that meet your various needs. When there is no product matches our standard products, we can flexibly customize by extracting elements you seek. We work together as one to solve your various problems such as projects “whose development was rejected by other companies”.

03

Speed and meticulous responsiveness

Our sales staff are professionals with expert knowledge and skills. We warmly respond to your problems and requests and we also try to propose quickly. We consider the balancing both speed and accuracy as essential for sure. We aim to being reliable for you by responding more promptly and politely than anywhere else.

The approach to optical technology

Technology

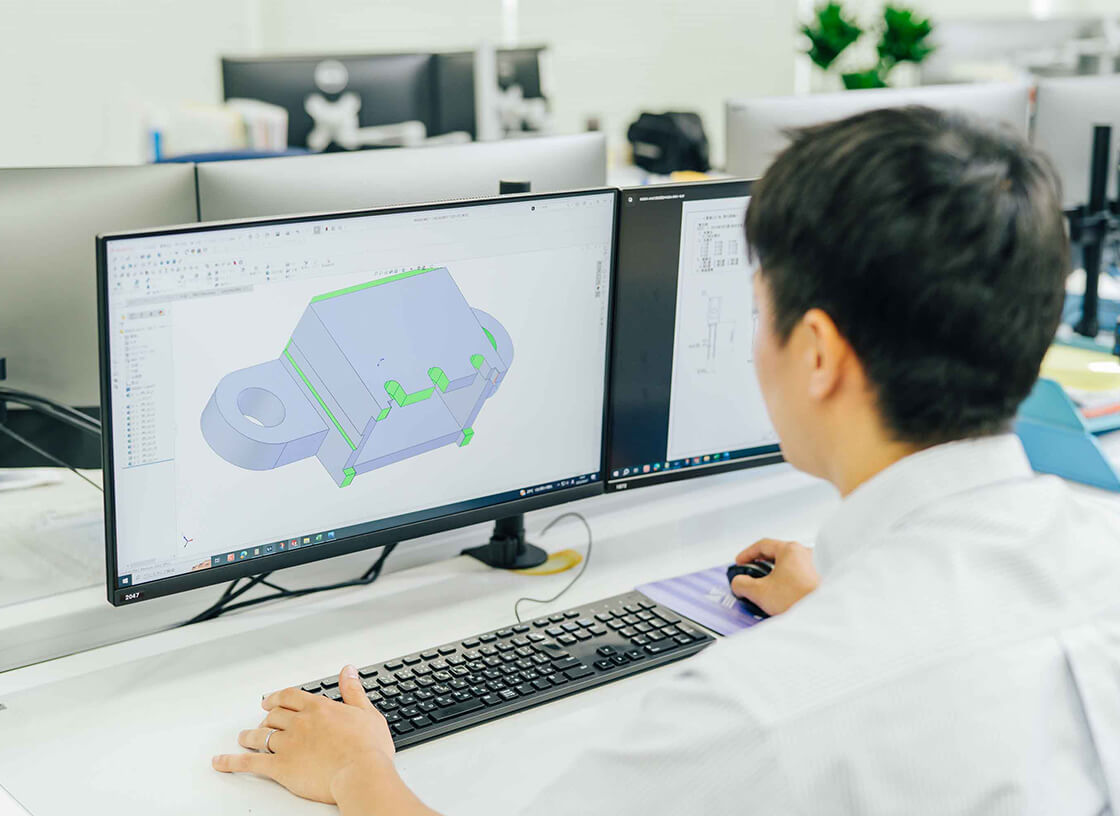

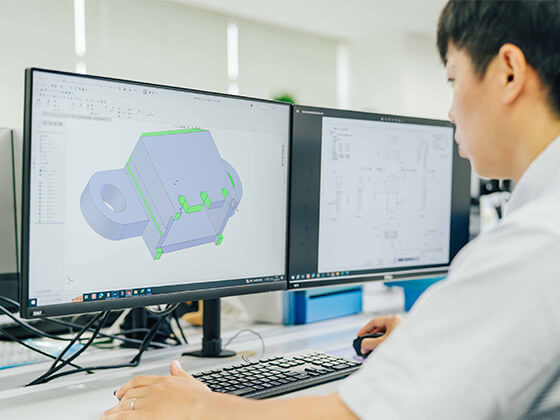

Shinkoh designs and develops products to suit customer’s particular needs, by taking advantage of leading-edge 3D CAD and optical software and doing advanced simulations.

Manufacturing

Updated equipments and skilled staffs manufacture products precisely and stably.

Furthermore, we unify technical know-how essential for productivity increases and constantly strive to improve it in the field.

Quality

The installation of X-ray analyzer and SEM(Scanning Electron Microscope) has made it easy to figure out the state of a product.

In addition, that has improved analytical capability and contributed to quality improvement.

Quality Assurance System

Quality management system

Shinkoh obtained ISO9001 certification in headquarters, Manufacturing Management Center, Tokyo sales office Nagoya sales office and Kansai sales office. Certification (PDF 193KB)

In accordance with recent revised content Shinkoh, as photo sensors and photo sensors unit manufacturer, continues to develop better quality control system with keeping manufacturing on ordinance observation and with making effort to satisfy customers.

| Certification | ISO90001 |

|---|---|

| Registration date | Nov 2009 |

| Authentication range | Photo sensor and LED, design and development of application products of the light-receiving element, manufacture and sales of motor |

R & D section

R & D team, in design process, carries out mechanical, optical design and simulation by using leading edge desgin tools for customer’s request. Ensuring mechanical consistency by 3D CAD, the problem occur beforehand, which can help to develop better products.

Moreover by using automatic measurement R &D team improves and innovates the design quality.

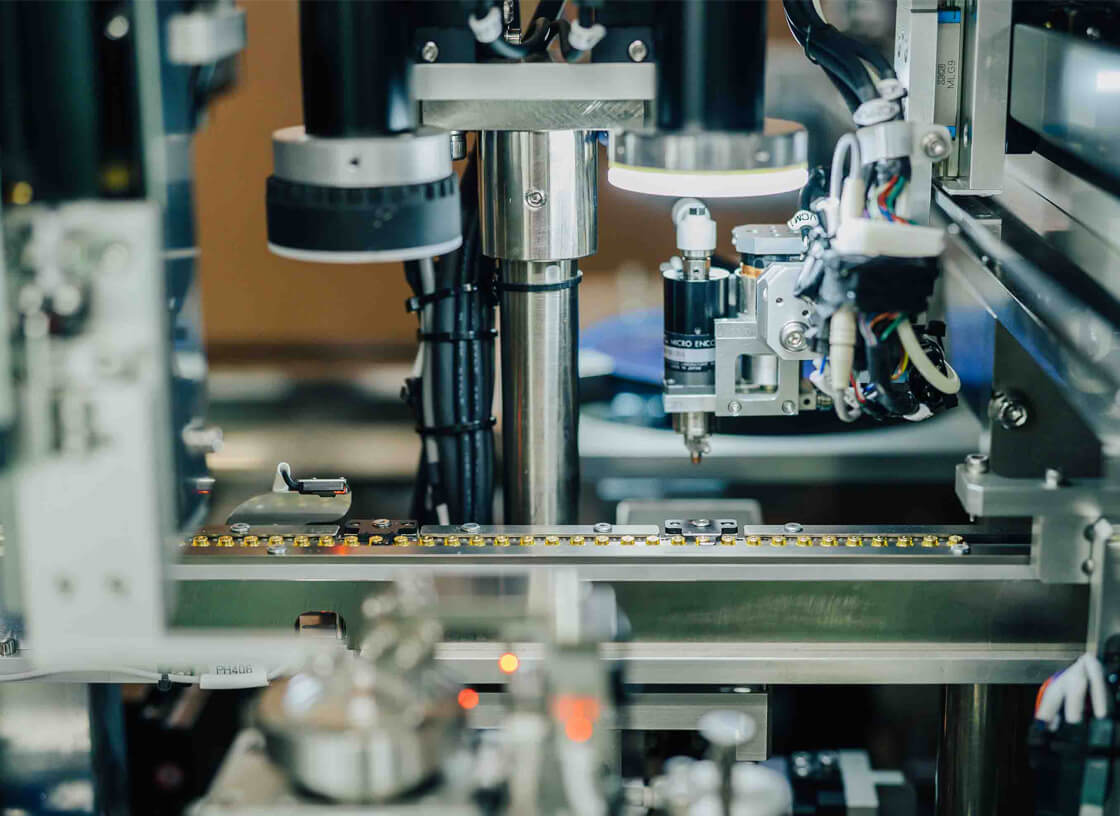

Production section

Automatic soldering machines and automatic appearance inspectors were installed in production section. Their goal is satisfying customers supplying more stable and higher reliable products. Manual soldering is also carried out by workers who are given education and recognized by our company. In order to keep traceability for a certain product, laser marking device was installed.

Lot management per package is not only success in our factory, lot management per products is also effective. Production section makes diligent fullfilling of requirements form customers.

Manufacturing control section

Purchasing department manages material by barcode and logistics flow to acceptance inspection in real time. Also Manufacturing control section checks strictly manufacturing process and quality in subcontract factory and is making efforts to maintain quality day to day.

Quality control section

Quality control promotes green procurement, RoHS compliant and REACH which are required for environment today and compiles a database. Additionally they manages and checks environmental load material like toxic materials, noise and pollution.

Facility

Shinkoh manages quality, automatize manufacturing process and installed leading-edge machines and equipments for the purpose of satisfying customers.

Clean room

Shinkoh has more than 300 square meters clean room to manufacture discrete semiconductors such as LEDs, Photo diodes, Photo transistors and COB(chip on board). Manufacturing process, storage of chip, assembly, forming process inspection can be carried out in this facility.

Equipment

Shinkoh have several automatic assembly equipments, inspection devices, evaluating apparatus related with production, assembly, inspection and storage for treating advanced technology of photo sensors.

| Assembling machine | 3D machining RP machine YAG laser marker CO2 laser marker Ultrasonic welding machine Automatic soldering machine Thermostatic Chamber Oven Manual die bonder Automatic die bonder Manual wire bonder Automatic wire bonder Resin filling machinery |

|---|---|

| Measurement machine | Automatic characteristic sorter 3D automatic positioning stage Microscope with measurement device 3D digital scope 3D automatic measurement device Automatic PC substrate inspector Curve tracer Digital oscilloscope Digital programmable generator Multi meter Digital pico amp meter PLC circuit inspection device |

| CAD tool | 3D CAD 2D CAD Optical design software PC circuit design software |

| Analysis Instrument | X-ray Inspection system Scanning electron microscope |